What is Quality?

Quality is not an act, it is a habit and it has to be caused, not controlled

TIPS: IT IS EASIER TO SAVE 10 DOLLARS IN HUNDRED DIFFERENT PLACES

- THAN 1000 DOLLARS IN ONE PLACE .

- THAN 1000 DOLLARS IN ONE PLACE .

Quality means doing it right when no one is looking.

So, what is our business?

- it is not determined by the producer, but the customer.

- P. F Drucker

QUALITY = PRODUCTIVITY = PROFITABILITY

and the key to a successful organization is

LEADERSHIP

- it is not determined by the producer, but the customer.

- P. F Drucker

QUALITY = PRODUCTIVITY = PROFITABILITY

and the key to a successful organization is

LEADERSHIP

Focus on the customer

Have you quality costs running amok? Long lead times and late deliveries? A lot of customer complaints? Unreliable suppliers? Do new environmental laws and labour laws confuses You?

What the heck are 5S, PDCA and Lean anyway? Poor understanding of the markets?

- You have delivered the wrong or a defect product. What do you do?

- You have done a service but the customer is dissatisfied! Excuses!

- Yes, we try fix the problems accordingly as they arise. The cost ????... Hum, no clue!

- We want to fix the problems at the source but can not find the cause!

- Do your costs run amuck due to poor quality? Do not know. What is quality costs?

There is probably one thing that we can predict with certainty today,

by the time tomorrow comes, our markets will have changed

Have you quality costs running amok? Long lead times and late deliveries? A lot of customer complaints? Unreliable suppliers? Do new environmental laws and labour laws confuses You?

What the heck are 5S, PDCA and Lean anyway? Poor understanding of the markets?

- You have delivered the wrong or a defect product. What do you do?

- You have done a service but the customer is dissatisfied! Excuses!

- Yes, we try fix the problems accordingly as they arise. The cost ????... Hum, no clue!

- We want to fix the problems at the source but can not find the cause!

- Do your costs run amuck due to poor quality? Do not know. What is quality costs?

There is probably one thing that we can predict with certainty today,

by the time tomorrow comes, our markets will have changed

Your customers expect 100% foolproof items, products and services. When non-conformance, problems and defective products occur in the processes, not only unwanted interference, but also large costs are added to the business and affects the profitability. To remain competitive and profitable, companies must deal with quality problems and resolve them immediately and aggressively.

The need for continuous improvements and changes is therefore crucial for the competitiveness and profitability. Thus, a question of survival in an increasingly challenging and competitive market. A market where more and more jobs are out sourced to countries with cheaper labour. Your reputation, profitability and long-term success therefore depend on your possibility to adjust but also to a great extent on the quality of the materials, the products and services you deliver to your customers.

A business process always starts with the customer. Having stated this simple but true fact, I also have to say that the customer can abruptly end the business as well. We literally cannot be competitive in the market unless we can define our customers' needs and requirements. It is a mistake to think that a company could stay ahead of competition without continually improving itself.

However, it is fairly easy for an organization to go downhill and out of business by making the wrong decisions.

So the sense morale is; it always comes down to leadership, how flexible we are to adapt to ever changing new

philosophies and market trends. Adapt to the new ways.

QUALITY = PRODUCTIVITY = PROFITABILITY

and the key to a successful organization is

LEADERSHIP.

Strategic Business & Organizational development

The need for continuous improvements and changes is therefore crucial for the competitiveness and profitability. Thus, a question of survival in an increasingly challenging and competitive market. A market where more and more jobs are out sourced to countries with cheaper labour. Your reputation, profitability and long-term success therefore depend on your possibility to adjust but also to a great extent on the quality of the materials, the products and services you deliver to your customers.

A business process always starts with the customer. Having stated this simple but true fact, I also have to say that the customer can abruptly end the business as well. We literally cannot be competitive in the market unless we can define our customers' needs and requirements. It is a mistake to think that a company could stay ahead of competition without continually improving itself.

However, it is fairly easy for an organization to go downhill and out of business by making the wrong decisions.

So the sense morale is; it always comes down to leadership, how flexible we are to adapt to ever changing new

philosophies and market trends. Adapt to the new ways.

QUALITY = PRODUCTIVITY = PROFITABILITY

and the key to a successful organization is

LEADERSHIP.

Strategic Business & Organizational development

To run a successful business/organization all customer requirements, all tasks, process flows,

available capacity, material flow, and costs must be defined and applied.

To lead, manage and control - a company needs simple, clear and relevant goals and objectives that

govern the business against set targets. Not only are we talking about budget variances and short term

thinking but also about goals and objectives, long-term thinking, how we create customer benefits

and value creation processes.

available capacity, material flow, and costs must be defined and applied.

To lead, manage and control - a company needs simple, clear and relevant goals and objectives that

govern the business against set targets. Not only are we talking about budget variances and short term

thinking but also about goals and objectives, long-term thinking, how we create customer benefits

and value creation processes.

Therefore, companies and organizations are to create value growth such as customer satisfaction, motivated and satisfied employees, positive engagement in society, and sustainable financial results.

A leadership commitment develops the organization and provides all employees the opportunity to develop and take responsibility and allocate necessary resources required to achieve the company's value creation processes and goals. Processes that create value for customers as well as reinforce quality from the inside out and the outside in.

So we are talking about increasing customer value, higher productivity and efficiency, and long-term competitiveness, which require systematic procedures and decision-making. Employee participation, involvement and motivation are crucial. Constant communication and information to all concerned is therefore of the highest priority.

So take Control of your Business Processes . . .

w What is, and how do we create customer value and awareness?

w Why do we do as we do?

w How can we make it better and more efficient?

w How do we define a business oriented approach?

A leadership commitment develops the organization and provides all employees the opportunity to develop and take responsibility and allocate necessary resources required to achieve the company's value creation processes and goals. Processes that create value for customers as well as reinforce quality from the inside out and the outside in.

So we are talking about increasing customer value, higher productivity and efficiency, and long-term competitiveness, which require systematic procedures and decision-making. Employee participation, involvement and motivation are crucial. Constant communication and information to all concerned is therefore of the highest priority.

So take Control of your Business Processes . . .

w What is, and how do we create customer value and awareness?

w Why do we do as we do?

w How can we make it better and more efficient?

w How do we define a business oriented approach?

Strategies for increased productivity

Being competitive in the market today is a good starting point, but unfortunately no guarantee being competive tomorrow. It is therefore important that every business- small as large - are effective, not least in their production systems, and maintain an internationally high level of competitiveness.

At the same time it is a question of attitude, as we all work in a global economy. Therefore we must adopt a different view of profitability and short- and long term goals of our enterprise, looking beyond quarterly profits and ask ourselves if we want to remain in the market for two years, five years - ten years to come? And that is what we want, right?.

It is therefore necessary to focus our resources on the business core areas than on activities that do not add any lasting value or customer value to the customer. To prevent unwanted costs incurred that are added to the business and affects profitability negatively. Creating customer value.

The need for improvements and changes are therefore crucial for the productivity, competitiveness and profitability.

w Total quality: In the products, in processes, in relations between customers, suppliers and employees.

w Productivity: Manufacture products and services cheaper, faster and more economical.

w Customer focus: Listen to your customer and how do we create customer value?

Being competitive in the market today is a good starting point, but unfortunately no guarantee being competive tomorrow. It is therefore important that every business- small as large - are effective, not least in their production systems, and maintain an internationally high level of competitiveness.

At the same time it is a question of attitude, as we all work in a global economy. Therefore we must adopt a different view of profitability and short- and long term goals of our enterprise, looking beyond quarterly profits and ask ourselves if we want to remain in the market for two years, five years - ten years to come? And that is what we want, right?.

It is therefore necessary to focus our resources on the business core areas than on activities that do not add any lasting value or customer value to the customer. To prevent unwanted costs incurred that are added to the business and affects profitability negatively. Creating customer value.

The need for improvements and changes are therefore crucial for the productivity, competitiveness and profitability.

w Total quality: In the products, in processes, in relations between customers, suppliers and employees.

w Productivity: Manufacture products and services cheaper, faster and more economical.

w Customer focus: Listen to your customer and how do we create customer value?

IS QUALITY FREE?

The old philosophy that QUALITY IS FREE, do the things right the first time should have both saved money and time for the companies. However, what we know for sure is that the cost of selling products and services that do not live up to the customers expectations, is almost impossible to measure.

Delayed deliveries, lost market shares, warranty claims, all these will accumulate to a considerable amount of money referred to as

QUALITY COSTS.

Costs of poor quality should be a primary concern of any business striving to get a competitive edge, and thus improve profits. So, just how well does quality improvement really pay?

That question is best answered by examining the cost of poor quality. Poor quality has a great impact on business performance. Typically, the cost of poor quality amounts to about 15 to 20% of sales, copying and handling defective components and products. Can be more, can be less.

COSTS THAT COME DIRECTLY OFF THE BOTTOM LINE

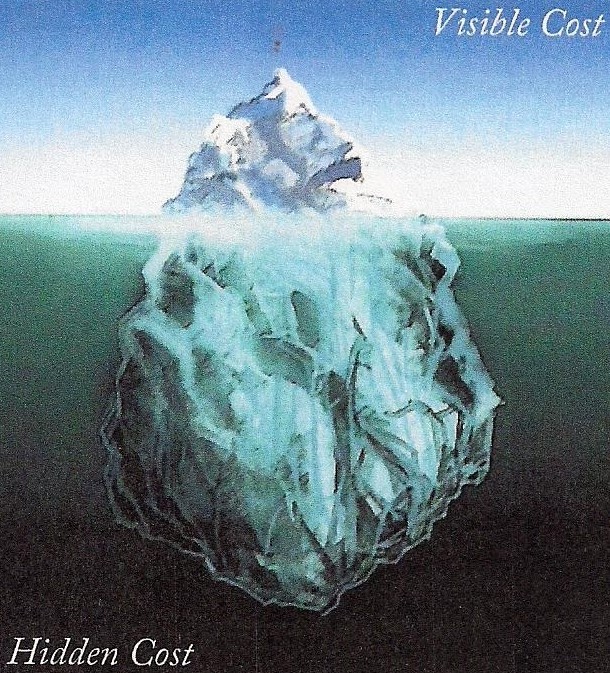

The "iceberg" picture below explains how many costs are hidden

The old philosophy that QUALITY IS FREE, do the things right the first time should have both saved money and time for the companies. However, what we know for sure is that the cost of selling products and services that do not live up to the customers expectations, is almost impossible to measure.

Delayed deliveries, lost market shares, warranty claims, all these will accumulate to a considerable amount of money referred to as

QUALITY COSTS.

Costs of poor quality should be a primary concern of any business striving to get a competitive edge, and thus improve profits. So, just how well does quality improvement really pay?

That question is best answered by examining the cost of poor quality. Poor quality has a great impact on business performance. Typically, the cost of poor quality amounts to about 15 to 20% of sales, copying and handling defective components and products. Can be more, can be less.

COSTS THAT COME DIRECTLY OFF THE BOTTOM LINE

The "iceberg" picture below explains how many costs are hidden

Iceberg of Poor Quality

However, most of these costs are hidden. The visible costs of poor quality, such as

scrap, rework, and warranty claims represent only the tip of the iceberg,

as shown in – Iceberg of Poor Quality. They usually amount to only a small part of the

total quality costs and normally do not attract management attention.

Companies that understand and attack those costs, and implement an effective quality

improvement program as a key competitive strategy can reduce quality costs, improve return on investment and profitability and increase market shares.

Measurement of quality costs is essential in convincing management. Of course long-term results

benefits are difficult to see immediately, and patience is not known to be a virtue of top-management

and fast profit seeking businesses.

But the necessity of achieving customer excellence in a tight market, is absorbing the interest from top management as they understand just how much poor quality is currently costing the company.

The management is always looking for profit and savings and this discussion should help executives

to see that high quality results in lower costs.

CONCLUSION

There are two kind of companies:

1) The first, the most typical company, views the customers complaints as a disease,

to be got over as quickly as possible.

2) The second, views customers complaints as a golden opportunity for improvements.

The lesson to be learned is that poor quality is very expensive and that

the company’s financial performance can be significantly enhanced

through a strategy of improvement. So choose the right road to

QUALITY = PRODUCTIVITY = PROFITABILITY

However, most of these costs are hidden. The visible costs of poor quality, such as

scrap, rework, and warranty claims represent only the tip of the iceberg,

as shown in – Iceberg of Poor Quality. They usually amount to only a small part of the

total quality costs and normally do not attract management attention.

Companies that understand and attack those costs, and implement an effective quality

improvement program as a key competitive strategy can reduce quality costs, improve return on investment and profitability and increase market shares.

Measurement of quality costs is essential in convincing management. Of course long-term results

benefits are difficult to see immediately, and patience is not known to be a virtue of top-management

and fast profit seeking businesses.

But the necessity of achieving customer excellence in a tight market, is absorbing the interest from top management as they understand just how much poor quality is currently costing the company.

The management is always looking for profit and savings and this discussion should help executives

to see that high quality results in lower costs.

CONCLUSION

There are two kind of companies:

1) The first, the most typical company, views the customers complaints as a disease,

to be got over as quickly as possible.

2) The second, views customers complaints as a golden opportunity for improvements.

The lesson to be learned is that poor quality is very expensive and that

the company’s financial performance can be significantly enhanced

through a strategy of improvement. So choose the right road to

QUALITY = PRODUCTIVITY = PROFITABILITY

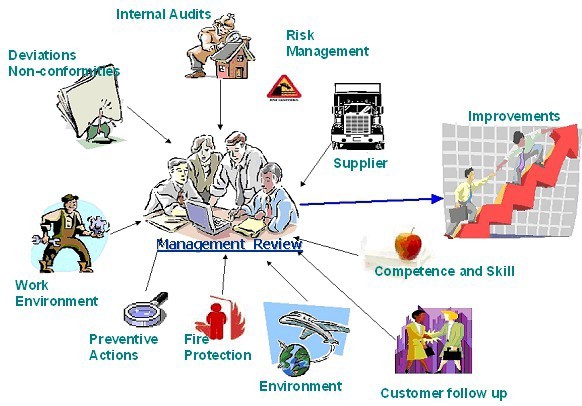

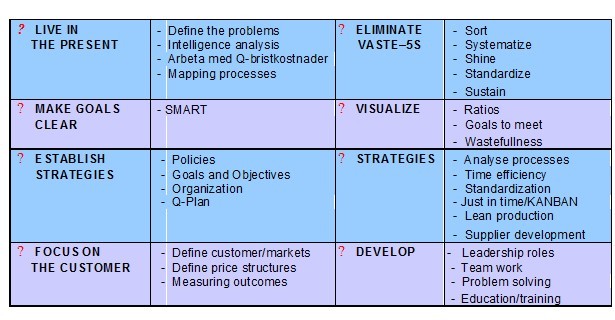

The following model - 8 simple steps gives a summary of the strategies and actions for higher quality and productivity,

which every company/organization/ business should implement and follow.

which every company/organization/ business should implement and follow.

So now take Control of your Business Processes . . .

CONTACT US FOR MORE INFORMATION

Hans Träff: +46 (0)730 617 086; Louise Brooks Träff: +46 (0)730 898 562; USA: +1 786 216 1698

E-post: hans@tqm-international-consultinggroup.com contact@tqm-international-consultinggroup.com

THANKS FOR YOUR INTEREST IN TQM-INTERNATIONAL CONSULTING GROUP

Hans Träff: +46 (0)730 617 086; Louise Brooks Träff: +46 (0)730 898 562; USA: +1 786 216 1698

E-post: hans@tqm-international-consultinggroup.com contact@tqm-international-consultinggroup.com

THANKS FOR YOUR INTEREST IN TQM-INTERNATIONAL CONSULTING GROUP

Sweden ¤ Europe ¤ Russia ¤ USA ¤ South America ¤ Asia ¤ Africa

Company- & Organization development ¤ Quality ¤ Environment

Work Environment ¤ Translations ¤ Education & Training

Work Environment ¤ Translations ¤ Education & Training

Passion for Quality

Management time

Engineering time

Increased inventory

Delivery problems Rejects

Lost orders Design changes

Extended warranty

Machine breakdown

Insufficient flow

Lack of procedures

Inefficient processes

Engineering time

Increased inventory

Delivery problems Rejects

Lost orders Design changes

Extended warranty

Machine breakdown

Insufficient flow

Lack of procedures

Inefficient processes

SCRAP

REWORK

WARRANTY

REWORK

WARRANTY

VISIBLE

COSTS

15 to 20 %

COSTS

15 to 20 %

TQM - international consulting grupp Team Gävleborg

Copyright 2012. TQM-international. All rights reserved. www.tqm-international-consultinggroup.com contact@tqm-international-consultinggroup.com

Copyright 2012. TQM-international. All rights reserved. www.tqm-international-consultinggroup.com contact@tqm-international-consultinggroup.com